Bring your innovative biobased process or product to the next scale.

A unique pilot facility for process development, scale-up and custom manufacturing of innovative biobased products and processes.

Bio Base Europe Pilot Plant is an independent, state-of-the-art facility that operates from a laboratory level to a multi-ton scale. Bio Base Europe Pilot Plant is a service provider for process development, scale-up and custom manufacturing of biobased products and processes. A wide and flexible spectrum of modular unit operations combined with the experience of our highly competent engineers and technicians enables us to translate your biobased lab protocol into a viable industrial process.

Bio Base Europe Pilot Plant enables the conversion of renewable feedstocks into biochemicals, biomaterials, biofuels and other bioproducts by using technologies such as biomass pretreatment, biocatalysis, (gas)fermentation, green chemistry and product recovery and purification.

Since its establishment in 2008, the Bio Base Europe Pilot Plant has grown into a mature organisation employing 180+ dynamic and engaged staff members. From 2013 to 2020, Bio Base Europe Pilot Plant successfully conducted more than 450 bilateral (private) projects with over 150 different small, medium and large sized companies. Along with private, bilateral projects, Bio Base Europe Pilot Plant is currently involved in many consortium-based projects.

Our History

Since its establishment in 2008, the Bio Base Europe Pilot Plant has grown into a mature organisation employing 180+ dynamic and engaged staff members. Check out our most important milestones in the timeline below. An overview of infrastructure investments can be seen in the animated video on top of the timeline.

-

2008

2008Start of the INTERREG VL-NL Project: "Bio Base Europe"

The INTERREG Flanders-Netherlands project “Bio Base Europe” kicks off. The budget foresees in € 13M for the conversion of an old fire station into a state-of-the-art pilot facility.

On Flemish side the project was co-financed by Flanders, the Province of East-Flanders and the City of Ghent. On Dutch side, the project was co-financed by the Dutch Ministry of Economic Affairs, the Province of “Zeeland”, Zeeland Seaports, ROC Westerschelde and Delta NV.

Staff count by the end of 2008: 3

-

2010

2010Inauguration of the first process hall dedicated to biomass pretreatment and biocatalysis

Two years after the start of the construction works, BBEPP inaugurates its first process hall, the “red” hall, dedicated to biomass pretreatment and biocatalysis.

Staff count by the end of 2010: 20

-

2011

2011Inauguration of the second process hall dedicated to fermentation and downstream processing

Three years after the start of the construction works, BBEPP inaugurates its second process hall, the “white” hall, dedicated to fermentation and downstream processing.

Staff count by the end of 2011: 22

-

2012

2012Inauguration of the third process hall dedicated to biomass green chemistry and ATEX proof processing

By the end of 2012, the Bio Base Europe Pilot Plant inaugurates its third process hall, the “green” hall, dedicated to green chemistry and ATEX proof processing.

Staff count by the end of 2012: 26

-

2013

2013Fully operational and immediately "break-even"

After five years of construction, as of 2013, the Bio Base Europe Pilot Plant is fully operational. This immediately results in a “break-even” at the end of the year.

In 2013, BBEPP also runs its first 4.5m3 fermentation.

Staff count by the end of 2013: 32

-

2014

2014Multi KET Demonstrator Pilot Line

In January 2014, the Bio Base Europe Pilot Plant was selected by the European Commission as a demonstrator multi-KET pilot line. KETs or Key Enabling Technologies (KETs) are considered to directly or indirectly stimulate Europe’s competitiveness and generate jobs, growth and wealth in the economy. Bio Base Europe Pilot Plant is and has always been a European front runner in terms of industrial biotechnology, one of the six European KETs.

Staff count by the end of 2014: 37

-

2015

2015Expansion of the fermentation capacity & Celebration 5 years BBEPP

In 2015, the fermentation scale and capacity is substantially expanded through the installation of two 1,500L and two 15,000L fermenters. One 15,000L fermentation line is co-financed by Interreg NWE; the other one by the European Regional Development Fund.

The new installation is inaugurated during the “5 years BBEPP” Event in June 2015.

Staff count by the end of 2015: 39

-

2016

2016First 15 m3 run; First Food Grade run

In 2015 Bio Base Europe Pilot Plant successfully executes its first 15m3 run as well as its first successful food grade run under the Food Safety System Certification 22000 (FSSC 22000).

Staff count by the end of 2016: 46

-

2017

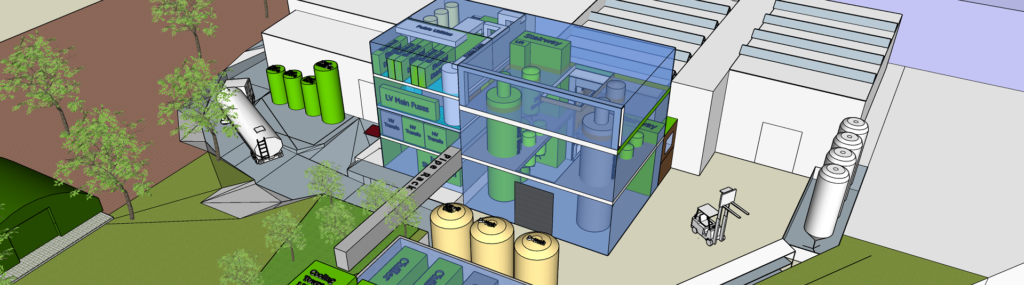

2017Construction of a new process hall. Investment in equipment for large scale DSP and gasfermentation.

In 2017, with the support from the IMPACT project, Bio Base Europe Pilot Plant starts the construction of a new process hall, including a media preparation and a spray dryer room. Furthermore, the IMPACT project invests in large scale downstream processing equipment and gasfermentation equipment.

An investment of roughly 9.4 M€, co-funded through the ERDF project “IMPACT” by the European Regional Development Fund, Flanders, The Province of East-Flanders and the City of Ghent.

-

2017

2017Start of the Pilots4U Network

In April the development of the Pilots4U Database and Network kicks off under the coordination of the Bio Base Europe Pilot Plant and funded under a CSA project within H2020-BBI-JU. Until today, BBEPP coordinates this European network of open access pilot and demonstration facilities.

More info: https://biopilots4u.eu/

-

2017

2017Bio Base NWE wins REGIOSTAR AWARDS

The Bio Base NWE project, coordinated by Bio Base Europe Pilot Plant from 2013 to 2015, won the RegioStars Award 2017 in the category ‘Smart Specialisation for SME Innovation‘. The winners of the RegioStars Awards 2017 were announced during a ceremony on October 10th, in the framework of the European Week of Regions and Cities in Brussels.

Staff count by end 2017: 69

-

2018

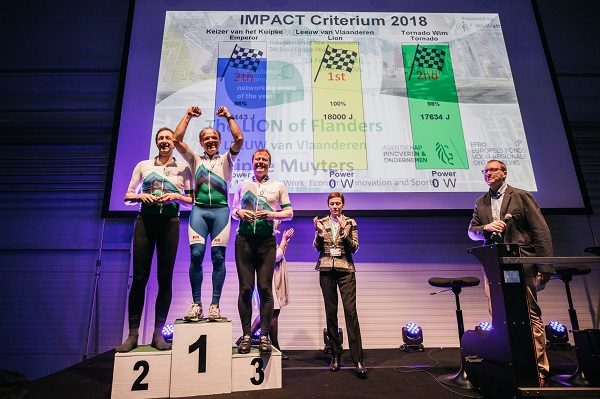

2018Inauguration IMPACT process hall for large DSP equipment

On February 19th, 2018, Minister Philippe Muyters inaugurates a new process hall for large downstream processing (DSP) equipment.

This process hall was built within “IMPACT”, an investment project for a total amount of €9,36 million and financed by the European Regional Development Fund (ERDF), Flanders, the Province of East-Flanders, the City of Ghent and the Bio Base Europe Pilot Plant. The financing was used to build up infrastructure specifically for gas fermentation and Downstream Processing.

Staff count by end 2018: 75

-

2019

2019Fermentation capacity raised by 6 x 150 L

In 2019, six extra 150 L fermenters become operational.

Staff count by end 2019: 84

-

2020

2020Start of the Bio Base FLOW investment project

Bio Base FLOW foresees in new tech transfer pilot equipment for industrial biotechnology and green chemistry. Furthermore, the project will also invest in partner hubs and project management rooms with integrated process control infrastructure.

Bio Base FLOW is supported by the European Regional Development Fund and Flanders Innovation & Entrepreneurship (VLAIO, Hermesfonds).

-

2020

2020SmartPilots and Pilots4U Final Event @ the European Commission

SmartPilots, an INTERREG Europe project coordinated by BBEPP, brought together the six leading European Shared Pilot Facilities in the field of bio-economy and their regional authorities with the aim to improve (regional) policies in support of shared pilot facilities. On February 4th, 2020, the consortium presented its policy recommendations (summarized in the video below) to the European Commission and European Parliament.

-

2020

2020The Bio Base Europe Pilot Plant counts 100 staff members!

In September 2020 we welcomed our HUNDREDTH staff members: Janne as a Bioprocess Technician and Arthur as Bioprocess Engineer. Welcome!

Staff count by end 2020: 103

-

2021

2021Installation of 565 solar panels

In 2021, Bio Base Europe Pilot Plant installed 565 solar panels on the roof of its process halls. The solar panels occupy a total surface of 1230 m² and generate approximately 200 Mwh/year, covering about one tenth of BBEPP’s total energy consumption.

Staff count by end 2021: 130

-

2021

2021Announcement of BBEPP's first spin-off company: Amphi-Star

In July 2021, BBEPP announces the establishment of its first spin-off company: AmphiStar. AmphiStar is developing a proprietary technology platform for the ecological production of biosurfactants (amphiphilic molecules). The platform is initially based on the glycolipid technology platform with the yeast Starmerella bombicola, that has been developed and scaled up in over 10 years by Ghent University (InBio research group) and the Bio Base Europe Pilot Plant (BBEPP).

AmphiStar has the mission to develop, scale up and demonstrate biosurfactant technology at industrially relevant level.

More information: https://amphistar.com/

-

2021

Announcement of € 28.33M of new investments to triple fermentation capacity

On October 8th, The Bio Base Europe Pilot Plant announced three new investments projects granted within the Flemish Resilience Relance Plan: Bio Base DEMO, Bio Base NEXTGEN Fermentation Platform and “Microbial Protein Transition” and a fourth investment project, Bio Base TRANSITION supported by VLAIO (Flanders Innovation & Entrepreneurship). In total, this investment of €28,33 million will allow the Bio Base Europe Pilot Plant to triple its fermentation capacity by the the end of 2023. The new equipment includes a.o. three extra 1,500 L bioreactors, an extra 15,000 L bioreactor, a 7,500 L and a 75,000 L bioreactor.

-

2022

2022Announcement of the establishment of the Bio Base Asia Pilot Plant

On April 22nd, 2022, during an online webinar, the Bio Base Europe Pilot Plant and the National Science and Technology Development Agency (NSTDA) in Thailand announced their 50/50 Joint Venture to establish the Bio Base Asia Pilot Plant.

The webinar revealed topics such as: Where the Bio Base Asia Pilot Plant is located, how and by when it will be operated, what services and technologies it will offer … and … particpants could even take a look inside the brand new facilities.

The webinar can be (re)watched using the following link: https://www.bohezproductions.com/bbapp-live.

-

2022

2022Inauguration of the Bio Base Mobile Pilot Plant

On June 15th, the Bio Base Mobile Pilot Plant was officially inaugurated. The inauguration was part of a site visit organised in the framework of the Final Symposium of the BIOCON-CO2 project,

Find out more by watching the video below:

-

2022

BBEPP, CAPTURE, Ghent University and ILVO launch The ProteInn Club

On June 23rd, a new innovation platform entitled “The ProteInn Club” has been christened. The platform will advance a fairly new (f)actor in the food landscape and the broader bioeconomy: proteins made through fermentation-based production processes. The ‘inn’ in the name refers to innovation.

Knowledge centers Ghent University (UGent), CAPTURE, ILVO and the pilot facility Bio Base Europe Pilot Plant (BBEPP) are the proud parents.

The ambition is to achieve a significant sustainability gain in the world of proteins, by accelerating the realization of new value chains on an industrial scale. 30+ companies already engaged in the Industrial Sounding Board that will set out the agenda for The ProteInn Club.

More information on The ProteInn Club can be found here: https://theproteinnclub.eu/

-

2023

20238 x 30 L Stainless Steel Bioreactors, 3 x 1,500 L Bioreactors and 1 extra 15,000 L Bioreactor operational!

From July 2023 onwards, the Bio Base Europe Pilot Plant has extra fermentation capacity with the commissioning of:

- Eight 30 L stainless steel bioreactors,

- Three new 1,500 L bioreactors

- and an extra 15,000 L bioreactor.

In total, BBEPP has now 8 operational 30 L stainless steel bioreactors, 5 operational 1,500 L and 3 operational 15,000 L bioreactors.

This extra capacity was supported by the Bio Base NEXTGEN, Bio Base TRANSITION and Bio Base DEMO projects.

Still ongoing, the installation a our very first 75,000 L bioreactor, commissioning foreseen in Summer 2024. Stay tuned!

-

2023

75,000 L bioreactor safely installed into its dedicated process hall

August 17th, 2023, a day to always remember at the Bio Base Europe Pilot Plant as our very first 75,000 L bioreactor arrived and was safely installed in its dedicated process hall.

This investment was kindly supported by the Bio Base DEMO project and will be operational by August 2024.

-

2023

BBEPP invests in additional purification equipment, online sensors and water purification

The Bio Base Europe Pilot Plant engages in two new investment projects supported by the European Regional Development Fund: Bio Base Advance and Bio Base Release. After the previous investment round announced at the end of 2021 and enabling a tripling of the fermentation capacity, this now involves a total investment of almost €6M in additional purification equipment, online sensors and water purification. This brings the post-covid investments at the Bio Base Europe Pilot Plant to a total of 34.5 million euros.

Bio Base ADVANCE

To accelerate the industrialization of such innovative processes and meet the high demand, BBEPP will, through the Bio Base Advance project, invest in additional equipment for the purification of microbial protein from the fermentation medium, as well as in infrastructure for local and effective treatment and analysis of the process waters produced. The new infrastructure will be equipped with automation and state-of-the-art sensors to enable process monitoring, control and modelling and therefore life cycle and techno-economic analysis from fermentation to wastewater treatment. This is to validate the expected lower ecological footprint.

Bio Base RELEASE

With Bio Base Release, BBEPP invests in specialized and state-of-the-art process equipment for, on the one hand, the process control and monitoring of (intracellular) fermentations, and on the other hand, in equipment to break open the cells and equipment to subsequently further fractionate and purify the mix of cell contents, fermentation medium and the desired product.

A Team of experienced engineers and technicians that can always find a safe and workable approach

At Bio Base Europe Pilot Plant, your processes are in the competent hands of highly trained engineers and bioprocess technicians. Our team stands for a vast amount of know-how on both a scientific and technical level. Combined with decades of experience in scale-up and operating industrial equipment, our engineers translate your lab scale process into a viable industrial process.

The Bio Base Europe Pilot Plant team provides services to customers in full confidentiality. We run the innovative processes, feasibility trials and process optimizations in agreement with our customers’ demands and report in a transparent way. A close communication throughout the project and your presence at our facilities during the pilot trials ensures a seamless technology transfer in both directions.

In addition, our engineers and process operators can assist in experimental set-up, process analysis and design, calculation of mass balances, and provide start-up assistance at an industrial scale.

webdesign

webdesign